Journey of a Diamond

Rough to Retail

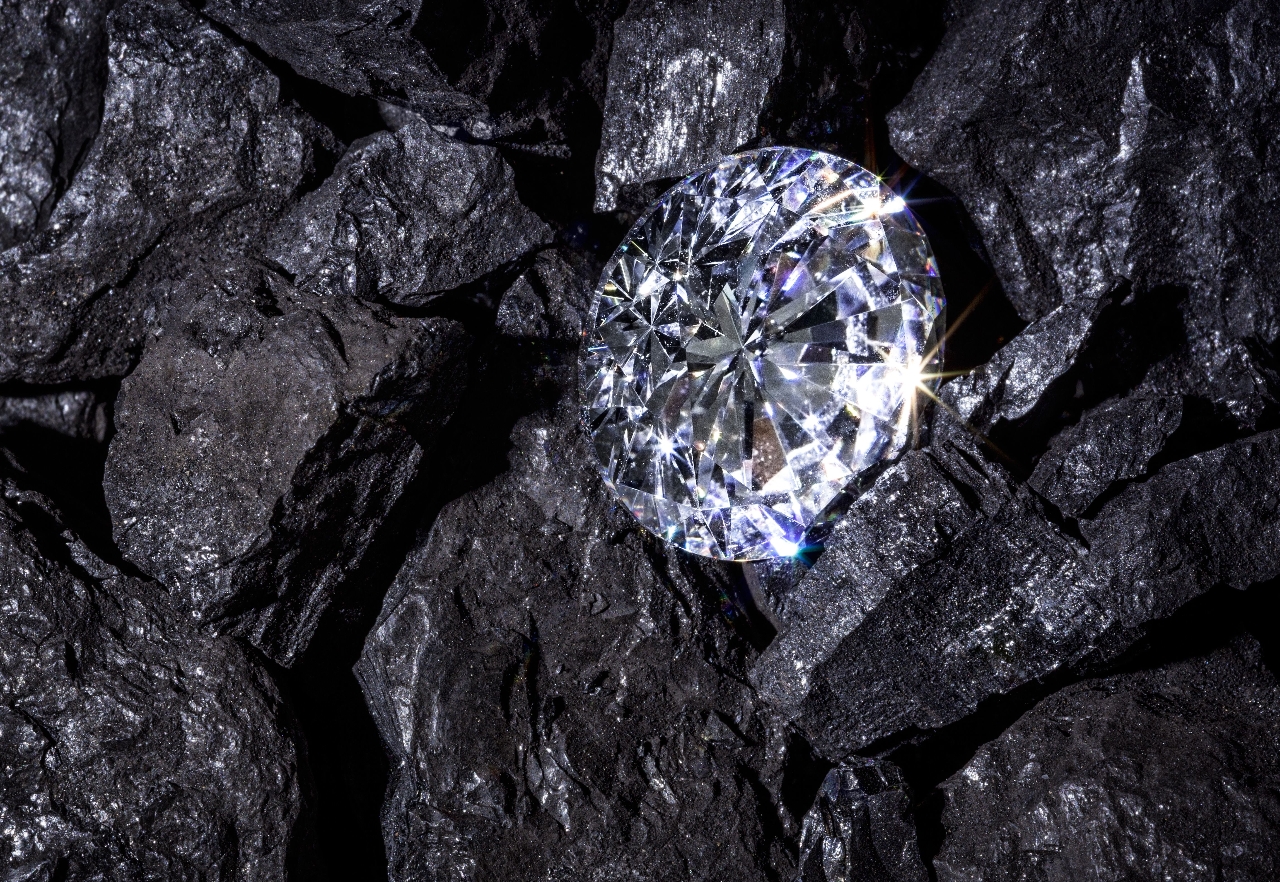

1. Exploration

Diamond exploration involves geological surveys, remote sensing, and geochemical sampling to locate kimberlite pipes and alluvial deposits. Drilling and core sampling help confirm the presence of diamond-bearing rocks, while indicator minerals guide exploration. In alluvial areas, sediment is analyzed for diamonds washed from primary sources. Environmental and economic assessments ensure the feasibility of mining before extraction begins.

2. Mining

Diamond mining involves extracting diamonds from the Earth, primarily from kimberlite pipes or alluvial deposits. Mining techniques include open-pit mining, where diamonds are extracted from surface deposits, and underground mining for deeper deposits. Once the diamonds are located, they are carefully excavated and transported for further processing.

3. Sorting

After mining, diamonds are sorted based on factors like size, shape, and quality. Sorting separates rough diamonds from other materials using methods such as visual inspection, sieving, and advanced technology like x-ray sorting, which identifies diamonds by their unique properties. This step is crucial for determining the diamond’s value and suitability for cutting.

4. Cutting & Polishing

Cutting and polishing transform rough diamonds into finished gemstones. Skilled cutters use precise tools to shape the rough stone into specific facets, optimizing its brilliance and sparkle. Polishing follows, where the diamond is carefully buffed to enhance its clarity, luster, and visual appeal, making it ready for sale.

Carat

Measures the diamond's weight; larger carats mean bigger diamonds.

Color

Assesses colorlessness; graded from D (colorless) to Z (light yellow).

Clarity

Evaluates internal and surface flaws (inclusions); ranges from Flawless (FL) to Included (I).

Cut

Determines how well the diamond reflects light; includes brilliance, fire, and sparkle.